Stories & Videos

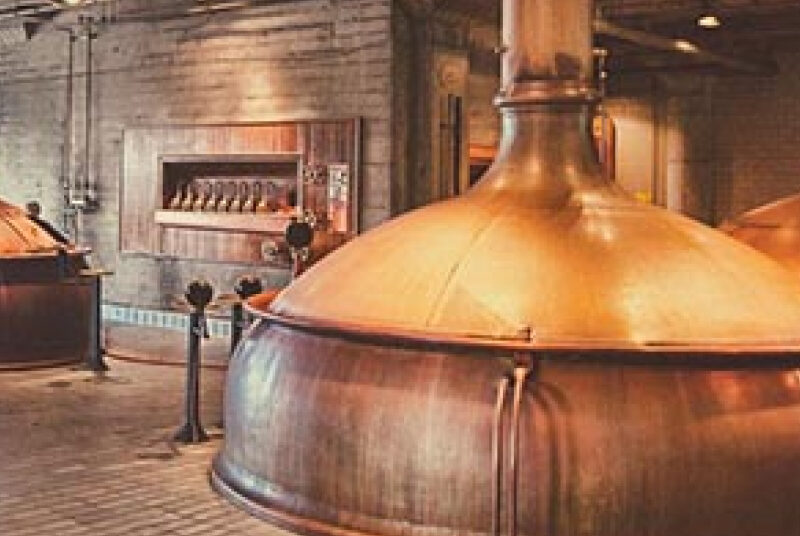

Forged in San Francisco in 1896, we are proud to be America’s First Craft Brewery. As we celebrate and honor our 125 years of trailblazing tradition, we’re looking ahead to our next 125. Anchors raised and full Steam ahead.

It’s that time of year again: San Francisco’s favorite week to celebrate the amazing beers of our city. We’re thrilled to offer up a number of awesome events jampacked with exclusive brews, pairings, and more! Check out our list and come Raise Your Anchor with us! Week Long Activities: CELEBRATE ANCHOR’S FLAGSHIP STEAM BEER WITH A LIMITED STEAM … Beer Lovers Rejoice! A week of beer, food, and fun with Anchor.

Once again, we’re proud to partner up with local nonprofit San Francisco Baykeeper and announce our limited-edition collaboration brew, Baykeeper IPA, in cans for the very first time. A San Francisco-style IPA, Baykeeper IPA is a crisp and refreshing, yet high ABV brew that brims with fruit-forward hop layers. Just in time for Baykeeper’s 30th anniversary … Introducing Baykeeper IPA in Cans – A Collaboration IPA That Supports Fierce Champions of the San Francisco Bay

Trying to think outside of the banquet hall for your next private event? Look no further than our brewhouse and tasting room! Our historic brewery offers a unique rental space for holiday parties, corporate gatherings, anniversaries, engagement parties, team outings, and, yes, even weddings. Situated in sunny Potrero Hill, our 1937 building is an architectural gem … Book the Brewery for Your Next Event

Anchor Brewing Company will once again celebrate America’s first handcrafted beer, Anchor Steam Beer, with the return of Anchor Steam Week August 11-18, 2019. Back in 2015, the city of San Francisco proclaimed the third week of August to be Anchor Steam Week, celebrating Anchor’s pioneering role in the American craft beer movement and continued … Anchor Steam Week 2019

We’re thrilled to announce our limited-edition collaboration brew, San Franpsycho® IPA, is back and in cans for the first time. Just in time for summer, this juicy IPA is more ready than ever for sunny hikes, days at the beach, or cheers around the campfire. Overflowing with stone fruit aromatics and strong floral hops, San Franpsycho® IPA is a pleasurable … Introducing San Franpsycho® IPA 12oz Cans!